Stiffness used for Deflection Calculations

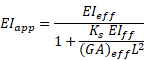

The apparent stiffness EIapp from NDS Equation 10.4-1

is not used by Sizer for deflection analysis except as a preliminary step, as it can create inaccurate shear deflection for some loading conditions. Sizer uses a rigorous implementation of shear deflection that is integrated into our matrix stiffness loads analysis.

The NDS procedure is used when searching for allowable sections before the parameters needed for rigorous shear deflection are known. It uses the shear deformation factor Ks = 11.5 value for uniformly distributed loads and simple-span pinned-pinned conditions. The calculation of the effective bending stiffness (EI)eff used in this equation is given in CLT Handbook 3.3.1 and O86 8.4.3.2 - Effective Stiffness.

Stiffness Used for Buckling Calculations (EI) app-min’

(EI) app-min’ is the factored effective stiffness modified for shear deflection. Although the E for pure bending is used to derive Emin for other materials, NDS Commentary C10.3.7 refers to “significant shear deformation that can occur between the parallel and perpendicular CLT laminations”.

EIapp is determined from EIeff using NDS Equation 10.4-1, then the formula from NDS Appendix Eqn. D-4 and Commentary Eqn. C4.2.4-1, is applied to get (EI) app-min. Finally the adjustment factors from NDS Table 10.3.1 (or Table 16.2.2. for fire design) are applied to get EIapp-min’.

Note that Eqn. D-4 that is ordinarily applied to E to determine Emin includes a 1.03 factor to convert to pure bending, that is, to factor out the decrease in the published E from the true E to account for shear deflection. This factor has been included in (EI)app-min even though it is intended to include shear deflection.

Examples in the CLT Handbook and the AWC Technical Report 10 for fire design include the 1.03 factor, so it is retained in Sizer as well even though it is contrary to the intention of C10.3.7. Note that the lamination E values used to create EIeff include the 1/1.03 factor for shear deflection, so this just serves to eliminate this redundancy for buckling design.

Ks Factor for Column Buckling

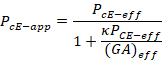

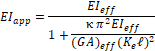

The Ks factor in Table 10.4.1.1 used to determine EIapp for column buckling is derived using the following expression from the literature on elastic stability, e.g. Timoshenko, Theory of Elastic Stability, 2.17, Eqn. 2-57:

κ is a standard factor for section shape, which equals 1.0 for CLT.

Then for each occurrence of a PcE in this equation, we substitute the expression for PcE given in NDS C3.7.1 (for column stability factor CP),and NDS 3.9 (for combined-axial-and-bending), i.e.,

PcE-app = π2 (EI)app / (Ke l) 2 and

PcE-eff = π2 (EI)eff. / (Ke l) 2 .

l is the unsupported length between lateral support points.

Then isolating EIapp on the left-hand side, you arrive at the following equation

which is the same as NDS Equation 10.4-1, with

Ks = κ ( π / Ke )2 .

L = l, the unsupported length (not the full span length L, despite what it says in NDS 10.4.1).

The values 11.8 and 47.4 for Ks in Table 10.4.1 are derived using the "recommended design" row from NDS Table G1 for Ke for pinned-pinned and fixed-fixed columns, respectively, with κ = 1.2 rather than κ = 1.0. However, following the advice of CSA O86 and APA, Sizer uses κ = 1.0.

Sizer allows pinned-fixed, pinned-pinned, and fixed-free columns, and allows you to enter your own Ke value, so Ks is calculated with the above formula and the Ke values that you input. The default values Ke of 0.8, 1.0, and 2.1, respectively, yield Ks values of 14.42, 9.87, and 2.23. This compares to the pin-pin value of 11.84 in NDS Table 10.4.1.